2025 PVC Packaging Film Market Growth Driven by Recyclable Solutions and Consumer Safety Focus

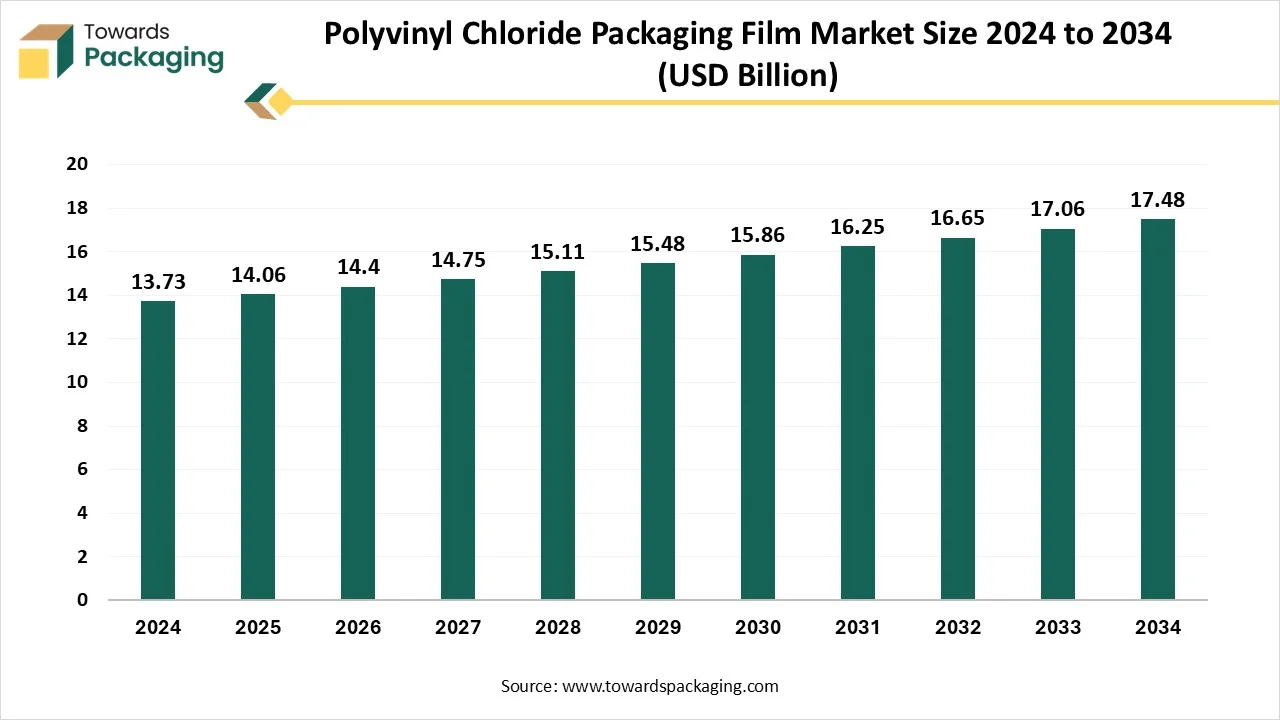

According to Towards Packaging consultants, the global polyvinyl chloride packaging film market is projected to reach approximately USD 17.48 billion by 2034, increasing from USD 13.73 billion in 2024, at a CAGR of 2.43% during the forecast period 2024 to 2034.

Ottawa, July 25, 2025 (GLOBE NEWSWIRE) -- The global polyvinyl chloride packaging film market size stood at USD 14.06 Billion in 2025 and is projected to reach USD 17.48 Billion by 2034, according to a study published by Towards Packaging, a sister firm of Precedence Research.

Get All the Details in Our Solutions – Access Report Sample: https://www.towardspackaging.com/download-sample/5647

The market is driven by strong demand across food, pharmaceutical, and medical applications due to PVC’s excellent clarity, barrier properties, and thermoformability. Asia‑Pacific dominates production and consumption thanks to robust downstream manufacturing, competitive labor, and rising packaged goods demand. In North America, regulatory frameworks supporting phthalate‑free and recyclable films alongside healthcare and food‑grade innovation accelerate adoption.

Technological advancements like thinner, high-performance, multi‑layer films, AI‑enhanced extrusion, and thermoplastic recycling improve efficiency and sustainability. Regulatory and environmental pressures are prompting innovation toward chlorine‑free, recyclable PVC formulations, lightweighting, and use of post‑consumer recycled content, strengthening future prospects.

What Are Polyvinyl Chloride (PVC) Packaging Films?

Polyvinyl chloride (PVC) packaging films are flexible, transparent plastic materials made from polyvinyl chloride resin, widely used for various packaging applications. Known for their excellent clarity, durability, and resistance to moisture, chemicals, and oil, these films are ideal for packaging food, pharmaceuticals, personal care items, and consumer goods. PVC packaging films offer superior shrinkage properties, which help tightly wrap products, preserving freshness and providing tamper-evidence.

PVC films are used in blister packs, clamshells, and flexible pouches due to their thermoform ability. Their ability to seal well and maintain product integrity during storage and transport further enhances their utility. Though PVC is a synthetic polymer, advancements in film production are increasingly focused on making it phthalate-free and recyclable to meet environmental standards. Moreover, PVC films are cost-effective, easy to print on, and compatible with various laminates and coatings, making them a preferred choice in industries seeking both functionality and attractive product presentation.

If there is anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

What Are the New Trends in The Polyvinyl Chloride (PVC) Packaging Films Industry?

-

Shift Toward Recyclable and Biodegradable PVC Films

Manufacturers are developing PVC formulas that are fully recyclable or compostable to meet circular‑economy goals and regulatory mandates.

-

Lightweighting and Material Efficiency

Industry players are reducing PVC film thickness without sacrificing performance, lowering raw material use, and reducing shipping emissions.

-

Use of Post‑Consumer Recycled (PCR) Content

PVC films increasingly incorporate recycled materials, helping brands reduce virgin plastic use and boost sustainability credentials.

-

Advanced Extrusion and Smart Additives

Extrusion improvements and new additives enable anti-fog, antibacterial, high-barrier, and phthalate‑free properties for enhanced protection and safety.

-

Integration of Smart Features

Smart PVC cling films now embed technologies like freshness indicators, QR codes, and NFC/RFID sensors for traceability and consumer engagement.

-

Customization for Branding & Design

PVC films are being produced with novel colors, patterns, and printable designs, catering to brand storytelling and visual differentiation.

What is the Potential Growth Rate of the Polyvinyl Chloride Packaging Film Market?

-

Rising Demand for Sustainable Packaging

Development of recyclable and phthalate-free PVC films offers eco-friendly solutions aligned with global sustainability goals.

-

Growth in the Healthcare and Pharmaceutical Sectors

Increasing use of PVC films in blister packs and medical packaging drives demand due to hygiene, barrier, and sealing properties.

-

Expansion of the Food and Beverage Industry

PVC films are ideal for wrapping and preserving perishable goods, offering extended shelf life and clear visibility.

-

Booming E-Commerce and Retail Packaging

Increased online shopping drives the need for durable, tamper-evident, and attractive packaging films.

-

Customization and Branding Opportunities

PVC films can be easily printed and customized, supporting brand visibility and product differentiation.

-

Increased Focus on Shelf Appeal and Transparency

PVC’s clarity helps showcase products attractively, especially in the food and cosmetic sectors.

Limitations & Challenges in Polyvinyl Chloride Packaging Film Market:

Environmental and Health Concerns & Stringent Regulatory Restrictions

The key players operating in the market are facing issues due to environmental and health concerns & stringent regulatory restrictions, which are estimated to restrict the growth of the polyvinyl chloride film market. PVC contains chlorine and additives like phthalates that can release harmful toxins during production and disposal, raising serious ecological and health issues.

Governments in Europe and North America have imposed strict regulations on PVC use and disposal, encouraging a shift to safer alternatives. Growing awareness of plastic pollution and toxic chemicals has led to declining consumer trust in PVC-based packaging.

More Insights of Towards Packaging:

- Vehicle Wrapping PVC Film Market - The vehicle wrapping PVC film market is forecast to grow from USD 5.07 billion in 2025 to USD 21.13 billion by 2034, driven by a CAGR of 17.18% from 2025 to 2034.

- Biopolymer Packaging Market - The global biopolymer packaging market is forecasted to expand from USD 26.74 billion in 2025 to USD 70.83 billion by 2034, growing at a CAGR of 11.43% from 2025 to 2034.

- Non-Recyclable Polystyrene Packaging Market - The non-recyclable polystyrene packaging market is accelerating, with forecasts predicting hundreds of millions in revenue growth between 2025 and 2034.

- Polyhydroxyalkanoates Films Market - The global polyhydroxyalkanoates films market is predicted to expand from USD 15.91 billion in 2025 to USD 36.76 billion by 2034, growing at a CAGR of 9.75%.

- Recycled Polypropylene in Packaging Market - The recycled polypropylene in the packaging market is set to grow from USD 9.85 billion in 2025 to USD 17.66 billion by 2034, with an expected CAGR of 6.73%.

- Metalized Biaxially Oriented Polypropylene Films Market - The metalized biaxially oriented polypropylene films market is set to grow from USD 7.74 billion in 2025 to USD 13.1 billion by 2034.

- Polyethylene Mailers Market - The global polyethylene mailers market is expected to increase from USD 3.5 billion in 2025 to USD 5.69 billion by 2034, growing at a CAGR of 5.54%.

- Expanded Polystyrene for Packaging Market - The expanded polystyrene for packaging market is forecasted to expand from USD 13.2 billion in 2025 to USD 29.52 billion by 2034, growing at a CAGR of 9.53%.

- Flexible Polyurethane Foam Market - The global flexible polyurethane foam market size reached US$ 5.95 billion in 2024 and is projected to hit around US$ 10.86 billion by 2034.

- Cross-linked Polyethylene Market - The cross-linked polyethylene market is anticipated to grow from USD 9.27 billion in 2025 to USD 16.96 billion by 2034.

-

Polycarbonate Sheet Market - The polycarbonate sheet market is anticipated to grow from USD 2.27 billion in 2025 to USD 3.56 billion by 2034, with a compound annual growth rate (CAGR) of 5.15%.

Regional Analysis:

How is the Opportunistic Rise of North America in the Polyvinyl Chloride Packaging Film Market?

North America is witnessing rapid growth in the polyvinyl chloride -packaging film market due to increasing demand from the healthcare, food & beverage, and consumer goods sectors. The region's strong pharmaceutical industry, especially in the United States, requires high-quality, tamper-evident packaging solutions like PVC blister films. Additionally, the rising trend of convenient and hygienic food packaging supports PVC film use.

Technological advancements, higher consumer spending, and a well-developed retail sector further fuel market expansion. Moreover, sustainability efforts are encouraging innovations in recyclable and phthalate-free PVC formulations, making the material more acceptable in an increasingly eco-conscious market environment.

U.S. Market Trends

The U.S. dominates the North American PVC packaging film market due to its advanced pharmaceutical industry, high healthcare spending, and strong demand for blister packaging. Additionally, the growing e-commerce sector and packaged food consumption fuel the need for durable and transparent PVC films. Technological advancements and a shift toward recyclable PVC variants also support market growth.

Canada Market Trends

Canada contributes steadily with increasing demand for flexible packaging in the food, beverage, and healthcare sectors. The country’s strict packaging regulations and sustainability goals are pushing innovation in safer, low-toxicity PVC films. Growth in urbanization and retail modernization also drives demand.

Who is the Leader in the Polyvinyl Chloride Packaging Film Market?

Asia Pacific dominates the polyvinyl chloride (PVC) packaging film market due to a combination of rapid industrialization, rising urban population, and expanding middle-class consumer base. Countries like China, India, and Japan have seen significant growth in the food & beverage, pharmaceutical, and personal care industries, major consumers of PVC films.

Additionally, the presence of cost-effective manufacturing capabilities, availability of raw materials, and growing demand for flexible and transparent packaging have strengthened the region’s market position. Government investments in healthcare infrastructure and increased adoption of modern retail and e-commerce channels further contribute to the region’s strong dominance in the PVC packaging film market.

China Market Trends

China leads the market due to its massive manufacturing base, low production costs, and robust demand in the food, pharmaceutical, and consumer goods sectors. The country’s strong export capabilities and increasing investment in healthcare and e-commerce further fuel demand for PVC packaging films.

India Market Trends

India is rapidly growing due to a booming retail sector, an expanding urban population, and increased consumption of packaged food and pharmaceuticals. Government initiatives like “Make in India” and rising demand for cost-effective packaging solutions also boost PVC film usage.

Japan Market Trends

Japan maintains a steady market presence with advanced packaging technologies and high-quality healthcare infrastructure. Its focus on hygienic and safe pharmaceutical packaging drives the demand for clear, tamper-resistant PVC films.

South Korea Market Trends

South Korea contributes through its strong cosmetics and electronics sectors, which require high-quality, customizable packaging films. Innovations in sustainable PVC formulations also gain traction here.

How Big is the Success of the European Polyvinyl Chloride Packaging Film Market?

Europe is experiencing notable growth in the polyvinyl chloride (PVC) packaging films market due to increasing demand for high-performance, recyclable, and safe packaging materials across industries. The region’s well-established pharmaceutical and food sectors rely on PVC films for protective, transparent, and hygienic packaging. Additionally, stringent EU regulations around sustainability and waste management are driving innovation in phthalate-free and recyclable PVC film variants. Countries like Germany, France, and Italy are investing in modern packaging technologies and circular economy initiatives, which support the shift toward advanced PVC applications. Rising consumer preference for safe and convenient packaging also contributes to the market’s steady expansion.

How Crucial is the Role of Latin America in the Polyvinyl Chloride Packaging Film Market?

Latin America is growing at a considerable rate in the polyvinyl chloride (PVC) packaging film market due to the expanding food and beverage sector, rising urbanization, and increasing demand for cost-effective and flexible packaging solutions. Countries like Brazil, Mexico, and Argentina are witnessing growth in the pharmaceutical and personal care industries, which rely on durable and transparent packaging, such as PVC films.

Additionally, the region's growing retail and e-commerce activities are boosting the demand for protective and tamper-evident packaging. Although environmental concerns exist, the affordability and versatility of PVC films continue to make them a preferred choice across multiple industries in Latin America.

How does the Middle East and Africa lead the Polyvinyl Chloride Packaging Film Market?

The Middle East and Africa region holds substantial growth potential in the polyvinyl chloride packaging film market due to the expanding food and beverage, pharmaceutical, and retail sectors. Countries like Saudi Arabia, the UAE, and Egypt are emerging as key markets driven by increasing consumer demand for hygienic, flexible, and durable packaging. The region is also witnessing growth in e-commerce, which further boosts demand for protective films.

North Africa, in particular, benefits from a strong industrial base and rising packaging needs. Additionally, government initiatives supporting sustainable packaging practices and recyclable PVC film development are creating new opportunities for local and global market players in the MEA region.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Segment Outlook

Layer Type Insights

The multi-layer type segment dominates the polyvinyl chloride packaging film market due to its superior barrier properties, enhanced durability, and versatile application across various industries. Multi-layer films combine different material layers, each contributing specific functionalities such as moisture resistance, oxygen barrier, and mechanical strength. This makes them ideal for packaging sensitive products like pharmaceuticals, perishable foods, and personal care items, where product protection and shelf life are critical.

Moreover, multi-layer PVC films offer excellent printability and compatibility with advanced sealing technologies, allowing brands to achieve high-quality, visually appealing packaging. Their flexibility in customization and ability to meet diverse industry standards further solidify their dominance in the PVC packaging film market.

The single-layer segment is currently the fastest‑growing layer type within the polyvinyl chloride packaging film market due to several key factors. Single-layer PVC films offer exceptional clarity, brightness, and uniform transparency, delivering a visually appealing presentation ideal for retail packaging and branding.

They are cost-effective and versatile, compatible with low- to high-speed packaging machines across manual, semi-, and fully automatic lines, particularly useful for products with simpler barrier requirements. Their simpler structure enables faster production turnaround, reduced material cost, and easier recyclability, aligning with growing sustainability expectations. These films are especially suited for applications where moderate barrier performance suffices, while enabling clear product visibility and efficient packaging operations.

Packaging Type Insights

The flexible packaging segment holds dominance in the polyvinyl chloride packaging film market due to its exceptional versatility, cost-efficiency, and ability to cater to diverse end-use industries. Polyvinyl chloride films used in flexible packaging offer excellent clarity, barrier protection, and printability, making them ideal for consumer-driven sectors such as food and beverages, personal care, and pharmaceuticals.

The lightweight nature of flexible polyvinyl chloride packaging reduces transportation costs and environmental impact, aligning with sustainability trends. Additionally, its adaptability to various product shapes and sizes, combined with advancements in sealing and lamination technologies, further enhances its utility.

The growing demand for convenient, resealable, and visually appealing packaging formats also drives the preference for flexible polyvinyl chloride films. These films support rapid packaging operations, extended shelf life, and improved product visibility, making them a preferred choice for manufacturers seeking efficiency and brand differentiation.

The rigid packaging type segment is experiencing the fastest growth in the polyvinyl chloride packaging film market due to several key factors. Rigid polyvinyl chloride films deliver robust protection, structural stability, and tamper-evidence crucial for packaging sensitive items like pharmaceuticals, healthcare supplies, and high-value consumer goods. With stringent safety and hygiene requirements in the medical and pharmaceutical industries, rigid packaging’s ability to maintain sterility and dosage integrity makes it increasingly preferred.

Moreover, there is a rising consumer expectation for premium, high-quality packaging presentation, which rigid formats support through vivid graphics and premium finishes. Advances in manufacturing technology, such as automated extrusion and thermoforming, are enabling higher efficiency, quality consistency, and customization options for rigid films, fueling adoption.

Extrusion Technology Insights

Cast film extrusion technology holds dominance in the polyvinyl chloride packaging film market due to its superior film clarity, uniform thickness, and high production efficiency. This technology enables the production of high-quality polyvinyl chloride films with excellent mechanical and optical properties, making them ideal for applications requiring transparency and durability.

The cast process allows for better gauge control and enhanced printability, which is essential for brand-centric packaging. Moreover, the ability to incorporate multiple layers with barrier properties supports the growing demand in the food, pharmaceutical, and personal care industries.

Its adaptability to diverse packaging formats, such as thermoformed trays, clamshells, and blister packs, further drives its dominance. Cast film extrusion is also favored for its relatively lower production costs at scale and compatibility with advanced automation technologies. As sustainability and high-performance packaging needs continue to rise, cast film extrusion remains a preferred technology for manufacturers using polyvinyl chloride in high-volume, precision packaging applications.

Blown film extrusion technology is the fastest-growing extrusion technology segment in the polyvinyl chloride packaging film market due to its versatility, cost-effectiveness, and ability to produce films with superior mechanical strength and barrier properties. This technology allows for the efficient production of thin, multilayer polyvinyl chloride films that are ideal for flexible packaging applications in food, pharmaceuticals, and personal care. Its capability to manufacture films with excellent puncture resistance and durability supports the rising demand for secure and protective packaging.

Additionally, advancements in blown film machinery have improved output rates and reduced material waste, making it an attractive option for manufacturers. The process also enables customization in film width, thickness, and layering, offering greater flexibility to meet specific packaging needs. As sustainability concerns grow, blown film extrusion supports the use of recyclable and downgauged polyvinyl chloride materials, further driving its adoption.

Application Insights

The food and beverage segment dominates the polyvinyl chloride (PVC) packaging film market due to multiple strategic advantages. PVC cling films excel at preserving freshness by forming an airtight seal that minimizes contact with air and microorganisms, significantly reducing food spoilage and waste.

The film's high clarity and gloss deliver excellent product visibility, boosting consumer trust and visibility at the point of sale. With broad adoption in applications ranging from fresh produce to meats, dairy, and ready‑to‑eat meals, PVC cling film meets hygienic and barrier requirements critical in the food sector. Its compatibility with modified atmosphere packaging (MAP) further extends shelf life for perishable goods, strengthening its appeal for food packaging use.

The pharmaceutical segment is the fastest-growing application segment in the polyvinyl chloride (PVC) packaging film market, anchored by several key drivers. Pharmaceutical use of PVC films, particularly in blister packaging, continues to surge, supported by increasing demand for unit-dose and medication adherence formats, which enhance patient safety and reduce dosing errors.

Regulatory mandates and greater scrutiny of drug packaging integrity are fueling the adoption of tamper-evident and moisture-resistant PVC blister films, especially in regions like North America, Europe, and Asia-Pacific. Rising prevalence of chronic illnesses and growth in solid-dose pharmaceuticals further elevate blister film volumes.

Meanwhile, technological innovation, including high-speed blistering machinery, recyclable high-barrier laminates (PVC/PVDC), and smart sensor-enabled packs integrated with serialization and IoT, supports stronger growth in this application segment.

End-Use Insights

The packaging segment is the dominant end-use segment in the polyvinyl chloride packaging film market due to the widespread and versatile use of polyvinyl chloride films across multiple packaging applications. These films offer excellent clarity, durability, chemical resistance, and flexibility, making them ideal for packaging in the food, pharmaceutical, personal care, and consumer goods industries. Polyvinyl chloride films are widely used for blister packs, shrink wraps, cling films, and thermoformed containers, offering both aesthetic appeal and product protection.

Their compatibility with various printing and sealing technologies enhances branding and shelf appeal. Additionally, the growing demand for tamper-evident and hygienic packaging has reinforced the need for high-performance polyvinyl chloride films. With advancements in sustainable formulations and recyclability, manufacturers continue to prefer polyvinyl chloride in meeting both performance and environmental goals.

The healthcare end-use segment is the fastest-growing in the polyvinyl chloride packaging film market due to rising demand for safe, sterile, and tamper-evident packaging. Polyvinyl chloride films are widely used in blister packs for tablets and capsules, medical device packaging, and IV bags. Their excellent clarity, chemical resistance, and sealing properties make them ideal for pharmaceutical and hospital use. Increasing global healthcare expenditure, chronic disease prevalence, and regulatory focus on hygienic packaging further drive this segment's rapid growth.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in the Global Market:

- In June 2025, the INEOS cracker in Lavera, France, received its first deliveries of pyrolysis oil obtained from recycled plastic waste in order to produce virgin-quality polymers. By converting the cracker and gaining access to pyrolysis oil, INEOS is developing the capacity to assist clients in fulfilling the strict regulatory requirements and sustainability objectives of the EU. INEOS is actively working to increase the contribution of advanced recycling to the circular economy in conjunction with mechanical recycling, especially for high-performance applications.

- In March 2025, LyondellBasell, a leader in the global chemical industry, revealed the introduction of the polypropylene impact copolymer named Pro-fax EP649U for rigid packaging. The Pro-fax EP649U has excellent flow characteristics and quick crystallization, which make it possible to produce thin-walled containers quickly and effectively while improving output and product quality. On high-speed filling lines, the additive package in Pro-fax EP649U makes mold release simple, lowers static, and enhances downstream handling.

Top PVC Packaging Film Market Players

- Berry Global

- Sealed Air Corporation

- Mondi

- Sonoco Products Company

- Uflex Limited

- Sigma Plastics Group

- Bemis Company

- Jindal Poly Films

- Winpak Ltd

- Alpha Packaging

- Ecoplast LTD

- Printpack

- Supreme Industries

- Time Technoplast Ltd

Global Polyvinyl Chloride Packaging Film Market Segments

By Layer Type

- Single Layer

- Multilayer

By Packaging Type

- Rigid

- Flexible

By Extrusion Technology

- Cast Film Extrusion

- Blown Film Extrusion

By Application

- Food and Beverage

- Pharmaceutical

- Personal Care

- Industrial

By End-Use

- Packaging Industry

- Healthcare Industry

- Food and Beverage Industry

By Region

-

North America

- U.S.

- Canada

-

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

-

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

-

Latin America

- Brazil

- Mexico

- Argentina

-

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Invest in Premium Global Insights @ https://www.towardspackaging.com/price/5647

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Our Trusted Data Partners:

Precedence Research | Statifacts |Towards Automotive | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Web Wire | Packaging Web Wire | Automotive Web Wire

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.